Our commitment to a sustainable future

KIVO offers packaging solutions where sustainability and functionality go hand in hand. We strive to lead the industry by continuously innovating and providing high-quality, environmentally friendly products. By working with our partners and complying with the strictest regulations, we are building a future where quality and sustainability reinforce each other. "We Love Sustainable Plastics" reflects our pride and commitment to produce packaging that is efficient and has minimal impact on the environment.

- 100%

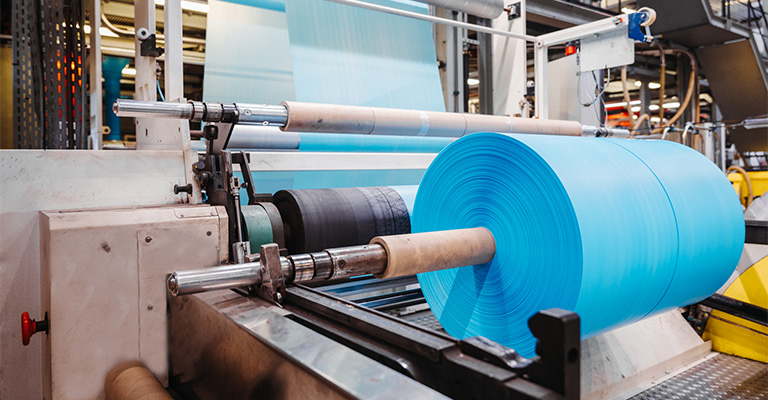

Production of PIR & PCR

Completely in-house with our own recycling facilities.

- 100%

Focus on sustainability & functionality

We produce packaging solutions where sustainability and functionality go hand in hand

Our mission

Vision of sustainability

Our vision is guided by the four core aspects of our sustainability policy: Reduce, Recycle, Redesign and Renew. We aim to reduce the thickness of our packaging, increase the use of recycled and bio-based materials, and design our products to be easily recyclable at the end of their life cycle. This approach not only illustrates our commitment to sustainability, but also underscores our forward-looking view of complying with strict and changing regulations.

Recycling and use of recycled materials (PIR and PCR)

At KIVO, we process production surpluses and waste streams into high-quality PIR and PCR raw materials. These recycled materials are then used to create new, sustainable packaging solutions, contributing to a circular economy and reducing the carbon footprint of our products.

Innovation and quality in sustainable packaging

Our packaging solutions combine efficiency, functionality and sustainability. By continuously innovating and using the latest technologies, we ensure that our products meet the highest quality standards and contribute to a more sustainable future.

PPWR-proof products

KIVO's focus is on developing packaging solutions that comply with the latest PPWR regulations. We help our partners navigate the complexities of sustainability regulations in the EU so that our products not only meet current standards, but also anticipate future challenges.

Core aspects of our Approach

Reduce (thickness and size reduction)

At KIVO, we strive to minimise material use through thickness and size reduction. By reducing the thickness of our films without sacrificing strength and functionality, we contribute to reducing raw material use and waste production. This not only ensures more efficient packaging solutions but also a lower ecological footprint.

Recycle (adding and increasing PCR content)

We integrate recycled materials into our products without direct food contact by adding and increasing PCR (Post-Consumer Recycled) content. By using high-quality recycled raw materials from our own recycling facility REKS LLC, we reduce dependence on virgin plastics and support a circular economy. Our advanced recycling techniques ensure that our packaging is sustainable, without compromising on quality.

Redesign (improving recyclability)

KIVO is constantly committed to improving the recyclability of our products. We design packaging that is easier to recycle by using mono-materials and eliminating non-recyclable components. This promotes the efficiency of recycling processes and helps our customers meet the strictest sustainability standards.

Renew (adding bio-based materials)

At KIVO, we research and implement the use of bio-based materials to make our packaging solutions even more sustainable. By adding bio-based materials where cost-effective for our customers, we reduce dependence on fossil raw materials and contribute to the reduction of CO2 emissions. Our biobased solutions are designed to be environmentally friendly without sacrificing performance and functionality.

Widely certified for durability and quality