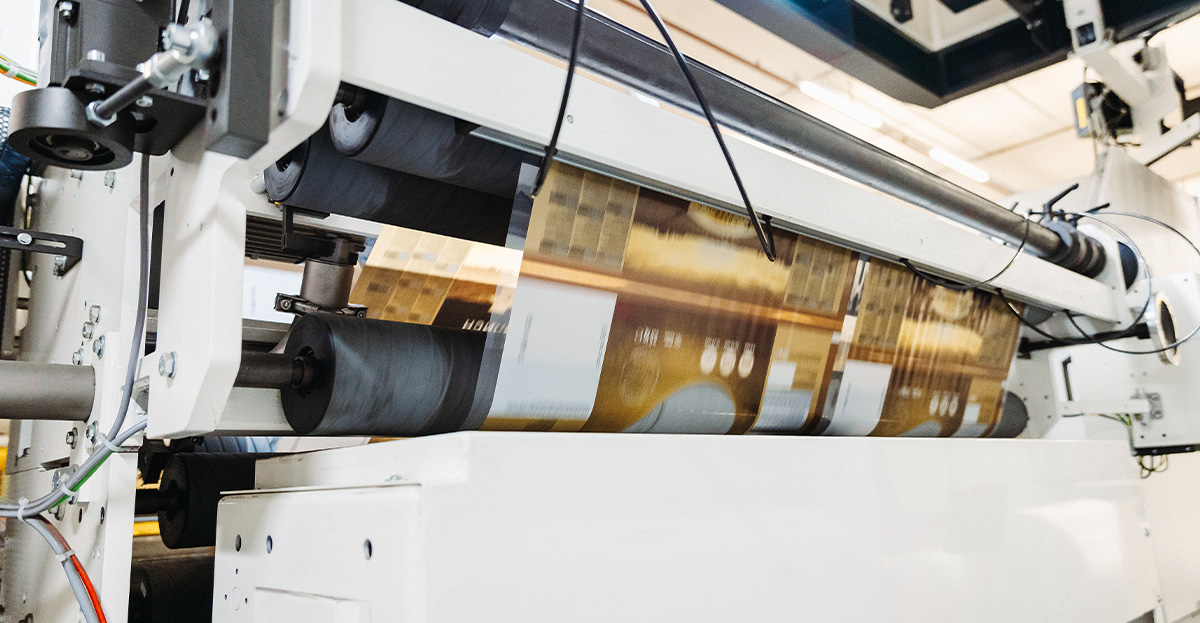

How flexo printing works

At KIVO, we are proud of our industry-leading flexo printing facility, equipped with state-of-the-art machinery capable of printing up to 10 colours. This process uses flexo techniques to deliver high-quality printing on all kinds of films. By proactively following and testing the latest developments, we remain at the top of the European flexo market. With our highly trained staff and award-winning quality, we ensure perfect colour consistency and environmentally friendly production.

Sustainable flexo printing

At KIVO, sustainability is at the heart of our flexo printing process. We minimise environmental impact by using fewer colours and reducing waste. Our afterburner neutralises alcohol vapours, so we comply with strict European laws and regulations. Innovative techniques allow us to achieve similar printing results with less ink, thus producing sustainable and environmentally friendly packaging.

Find out how our sustainable approach contributes to high-quality eco-friendly packaging solutions.

Our various flexo printing machines

At KIVO, we have an advanced machine park with several flexo printing machines, including a Miraflex (8 colours) and two Novoflex machines (8 and 10 colours). Both from the leading brand Windmöller & Hölscher. These machines are equipped with the latest technical gadgets, such as Kodak NX and GTT raster sleeve technology, and use highly pigmented inks from Doneck. Thanks to our high-quality colour management and viscosity control, we guarantee perfect colour quality and consistent printing results.

Frequently asked questions

Below are some frequently asked questions about our flexo printing processes.

What is flexographic printing and how does KIVO apply this technique?

Flexo printing is a printing technique that uses flexible plates (sleeves) to apply ink to various materials. At KIVO, we use state-of-the-art flexo printing machines to print up to 10 colours, ranging from simple to complex designs.

Which materials can be printed with KIVO's flexo printing technology?

We can print on a wide range of PE materials, including films for food packaging, industrial packaging, and special applications such as barrier film and freezer film.

How does KIVO ensure that flexographic printing is environmentally friendly?

We use eco-friendly inks and minimise ink consumption through efficient printing techniques. In addition, our afterburners ensure that harmful vapours are neutralised before they reach the atmosphere.

What makes KIVO's flexo printing machines unique?

Our flexo printing machines are equipped with the latest technologies, such as Kodak NX and GTT raster sleeve technology, ensuring superior print quality and consistency. This has also resulted in winning several prestigious awards within the printing industry.