Ever since its establishment, KIVO has proven itself through developments that help customers move forward. You notice this not only in our quality, but also in cost savings and sustainability. A new recent development in the field of sustainability is the achievement of ISCC PLUS MBA certification. ISCC , which stands for International Sustainability and Carbon Certification, is an advanced programme and the first globally recognised certification scheme for biomass and bioenergy.

The system rests on four pillars:

- reduction of greenhouse gas emissions

- protection of land with high biodiversity

- deforestation-free supply chains

- environmentally friendly production to protect soil, water and air.

In the case of plastics, it concerns only material whose raw material is derived from renewable sources. This may include raw material obtained from mechanical (read also: what is mechanical recycling?) and chemical recycling (read also: what is chemical recycling?) from plastic waste, but also from oil from other sources such as wood waste or used frying oil.

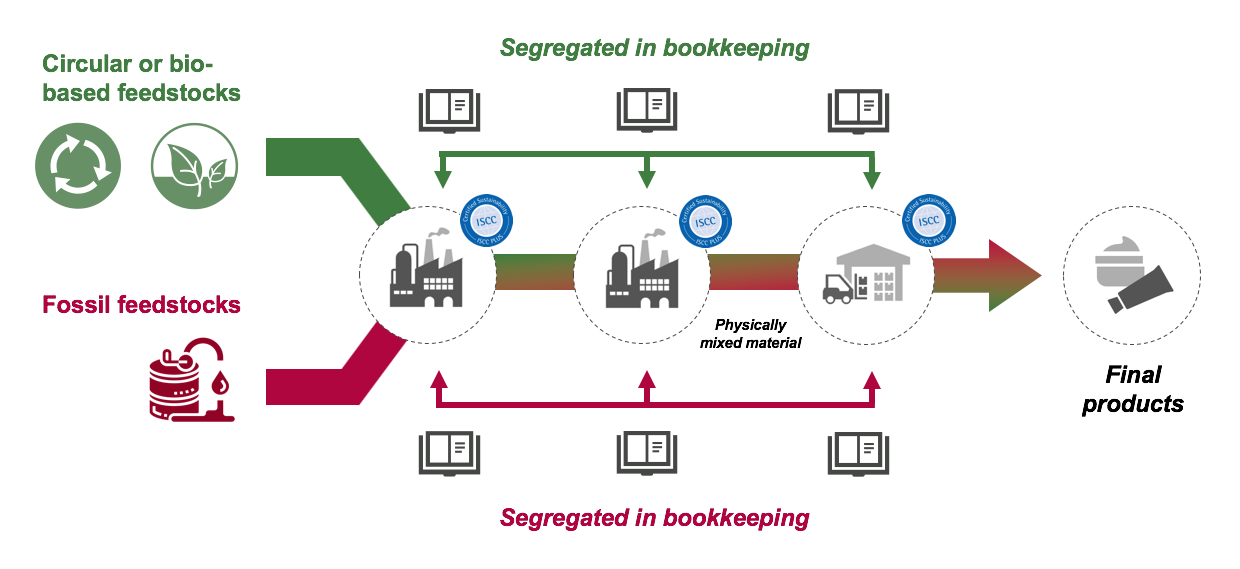

The volumes are currently too small to run production plants on. As a result, granulate producers are forced to blend those volumes with the fossil streams. In this way it is impossible to produce granulates with a fixed share of "green", but because it is certain that in the chain a share of green is present, you can buy that share as a user. The supplier must then properly administer how much green material has entered the system and how much green material is sold on paper. These 2 flows should be kept in balance.

This way of working, which we also know from the Green Certificates, becomes the Mass Balance Approach (MBA) called. This system can be rolled out throughout the supply chain, with the main condition for any system user: imports and exports of green material must be balanced. See Figure 1 for an illustration.

ISCC ensures that this process from monomer to finished product is carried out correctly. Each system user is audited separately and there are very strict conditions attached to certification. Green must really be green and false claims or unexplained differences between import and export must be prevented. KIVO has demonstrated that it meets these conditions and will make every effort to make this beautiful circular development a success.

After the fine developments in the use of recycled materials, this is another step that fits in with our aim to eventually produce flexible plastics that are the most functional AND environmentally friendly alternative for many applications.

For more info on ISCC and opportunities for deploying sustainable flexible films and packaging, then take contact with us.