HDPE stands for High Density Polyethylene and can be recognised by the crackling character of the film

Polyethylene is made by polymerisation of ethylene, a substance extracted from petroleum. HDPE film is made with a catalyst, through a low-pressure process. Because it is produced under low pressure, linear chains with few side branches are formed. This allows molecules to organise themselves well, resulting in a high degree of crystallisation. The higher the degree of crystallisation, the higher the density. This results in a strong, stiff, liquid-proof and wear-resistant film.

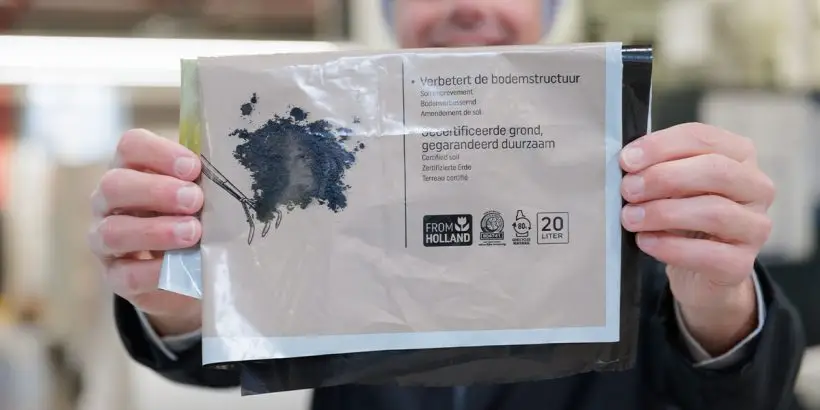

HDPE is widely used as a raw material for e.g. rubbish bags, hemmed bags and protective film.

Advantages of HDPE (film)

- HDPE is resistant to many industrial and live chemicals and can withstand the corrosion of strong oxidising agents, organic solvents and acid-based salts.

- HDPE is waterproof and non-hygroscopic (water-attracting).

- HDPE is highly machinable and suitable for fusion welding.

- HDPE is four to five times harder than LDPE-film and very strong and impact-resistant.

- HDPE has good UV resistance.

- HDPE is odourless and non-toxic. It is therefore also suitable for food packaging and clothing.

Another major advantage of HDPEfilm is that little material is needed to make a product. As a result, relatively little energy is needed for production. It also creates fewer CO2 emissions than other packaging materials because it is so light and low in volume. In addition, the material is easy to recycle. More on that below.

Do you have any questions following this article?

Then contact one of our experienced employees using the contact form below. You will then receive a response as soon as possible.