BRC certification, currently called BRCGS (British Retail Consortium Global Standards) stands for food safety and was developed in 1998 by the British Retail Consortium. It defines the requirements that organisations producing or packaging food must meet regarding quality and food safety. The various elements of the standard are tested against a detailed checklist containing more than 300 checkpoints.

Obtain BRC certificate

The standard for achieving a BRC certificate is made up of the following points;

- Food safety and quality policy

- Management commitment

- HACCP food safety plan

- Establishment standards

- Staff

- Process control

- Product control

When a company achieves BRC certification, it shows that the organisation meets the food safety requirements of the British Retail Consortium. This requires goodwill from management and decisiveness from the entire organisation in all parts of the BRC standard requirement.

BRC certification benefits

The benefits of obtaining BRC certification for an organisation are as follows:

- Recognition of the value of BRC certification by customers and clients

- Continuous improvement management

- Creating awareness of food safety

- GFSI-approved

- Meeting customer requirements

- Optimisation of the operating result

- Reduced risks and liability

- Demonstrable facts of food safety within the company

BRC quality mark

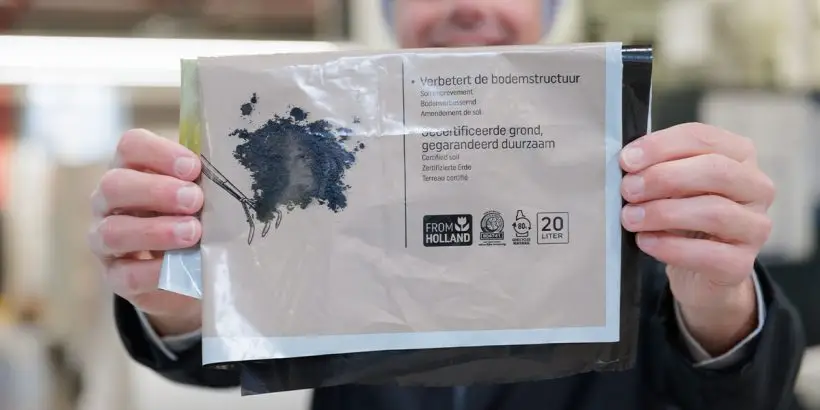

Below is the BRC seal of approval that we have managed to maintain year after year. It is reassessed every year against the latest laws and regulations. You receive this BRC hallmark after obtaining the BRC certificate and it helps companies that are in direct or indirect contact with foodstuffs to conduct their business operations according to the latest hygiene measures.

Are you looking for a BRC-certified plastic film producer in the Netherlands?

Then contact us with no obligation to discuss the numerous possibilities.

KIVO Flexible Plastics is currently one of the larger producers of HDPE film and LDPE film in Europe that also belongs in the list of BRC-certified companies.

Its main office is in Volendam, with another branch in the Netherlands (KIVO Zwolle) and two more branches in Kosovo, (KIVO LLC & REKS). KIVO markets a variety of LDPE- and HDPE-based products in both mono- and coextruded versions. Not only semi-finished products for the processing industry, but also finished products.