For automatic filling of products, packaging with a VFFS machine is often chosen. In this article, we explain the packaging using the VFFS method.

What does VFFS mean?

VFFS is an abbreviation for Vertical Form Fill Seal. It is a packaging system where products are packed vertically. Different packaging types can be made on the vertical machine. Various widths can be processed on these machines at high speeds (output). Finally, on the machine, the bag is formed and filled in a vertical way, hence the name Vertical Form Fill Seal (VFFS).

VFFS (vertical form fill and seal)

The automatic packaging process on the machine starts with a large roll film. The film is unwound and runs through the machine to the shoulder where the film is formed into bags and filled at the same time. This can be a variety of different packaging types, which can range from pillow bag to doypack. Depending on the width of the film and length of the bag, various weights can be packed. This packaging method is mostly used in the food industry also because of its flexibility and high processing speeds.

Vertical packaging machine

Pictured below is a vertical packaging machine (GEA Smartpacker CX400)

Figure 1.1

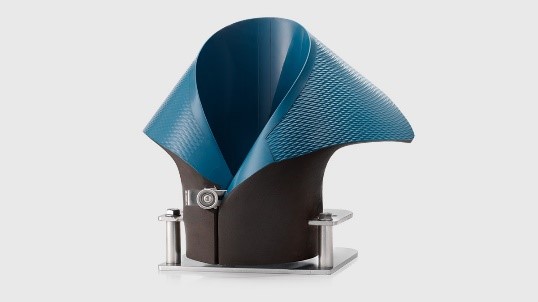

Below is the Centurion of VH Vertical Packaging BV displayed.

Figure 1.2

When the VFFS packaging machine is operational, a roll film unwound and guided through the packaging machine using the correct web tension. The film to create a filling shoulder (see Figure 1.2) after which it is formed into a bag. Simultaneously, a product is filled (vertically). After filling and sealing, the product is made and arrives on a conveyor belt for further packaging.

Figure 1.3

film for VFFS packaging machine

Depending on the product to be packaged, there are various qualities within KIVO films developed for VFFS packaging machines.

This can range from:

- high piercing resistance (for sharp and/or frozen products)

- high-stroke speeds (hot-tack)

- high gloss and transparency (for optical properties)

- excellent sealing properties (also peelable)

- wide sealwindow

- freezer resistance

- with or without barrier (EVOH)

- smooth or slip-resistant qualities

The high-quality, coextruded PE grades are thus tailored to your needs. In addition to the functional requirements, your wishes are also taken into account. In addition, in many cases we offer the possibility of bringing in a grade reduced in thickness that has the same functional properties as your current film/qualities. This leads to savings as, with a thinner thickness, more metres can be processed from the roll.

The PE-based films can be printed in up to 10 colours (see page on flexo printing) and are fully recyclable. We also offer the option of a film can be supplied with a proportion of recycled material. For your specific requirements and possibilities, please contact one of our specialists.

Do you have any questions following this article?

Then contact our product specialist with no obligation using the contact form below or email/call him directly using the contact details shown.