A LCA study is an environmentally focused method of mapping the impact of human activities and products on the environment. An LCA study looks at the entire life cycle of an activity or product.

The activity of a product starts with the extraction of raw materials through production and use of the product, or the reuse of the product (should it be recycled). It ends with the disposal of the product. In other words, from birth to the grave. Because different processes are analysed, an LCA study is considered a form of chain analysis.

Steps LCA study

LCA consists of a number of different steps for mapping the impact of products and human activities on the environment. The main steps are:

- LCI or: Life cycle inventory: In this step, all information related to the harmful substances emitted during the life cycle of the product or activity is collected. It also looks at which raw materials are used within the life cycle. Furthermore, other environment-related factors may also appear in an LCI, such as noise or odour production.

- LCIA or: Life cycle impact assessment: In this step, all data collected during the LCI (Life Cycle Inventory) process are assessed. This shows the environmental impact of the product or activity, and whether the product or activity is directly or indirectly responsible for it.

Score list

The outcome of an LCA study is a kind of environmental profile. This is a score list of all the environmental impacts the product or activity has. This profile shows which environmental impacts play the most important role in the life cycle.

An LCA study - in combination with related tools - can provide a concrete picture of what possible adjustments can be made in operations.

Initially, LCA was developed for assessing products. However, it can be used much more widely. As soon as a life cycle plays a role or a scoring list for a product adds value, LCA can be used.

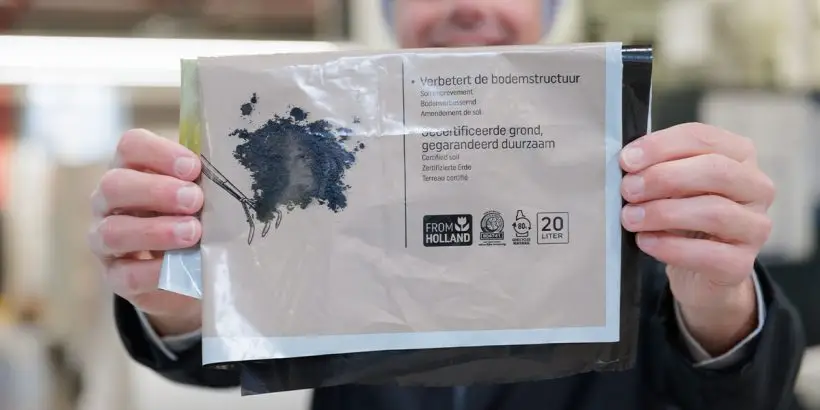

LCA study on plastic packaging

Curious about the environmental impact of your plastic packaging? Then get in touch with us. After a possible sustainability exercise, we can scientifically map out the environmental gains. Things that can reduce the environmental impact and where KIVO can help you are:

- Thinner films producing while maintaining mechanical properties

- Deployment of bio-based materials (read here: What are bioplastics?)

- Multilayer non-recyclable laminates replaced by recyclable laminates

- Deployment of recycled plastic, (both PIR and PCR) this can come from our own recycling plant REKS

Do you have any questions following this article?

Then contact one of our experienced employees using the contact form below. You will then receive a response as soon as possible.