Plastic does not just melt. Plastics react differently to heat: some soften, others liquefy. This depends entirely on the type of plastic. Just as metals have different melting points, each type of plastic also has a unique melting range. At what temperature does plastic melt? We try to answer that question in this article.

In this article, you will discover:

- What is the melting point of common types of plastic

- Which plastics are heat-resistant

- Why mixing plastics affects melting point

- Practical applications by type of plastic

Melting temperature of plastic: a real-life example

Consider a kettle. These are often made of polypropylene (PP), a plastic that only starts to melt at around 160°C. Because water boils at 100°C, the material remains stable and safe in normal use. This illustrates why it is crucial to choose the right plastic type for heat-sensitive applications.

Melting points of commonly used plastics

Polyethylene (PE): LDPE and HDPE

Polyethylene is a widely used plastic and comes in two varieties:

- LDPE (low-density polyethylene): melting point around 105°C

- HDPE (High-Density Polyethylene): melting point around 125°C

Both types are widely used in the packaging industry, e.g. for plastic bags, film and shrink packaging.

Polypropylene (PP)

- Melting point: about 165°C

- Properties: heat-resistant, lightweight, stiffer than PE

- Applications:

- Plastic coffee cups

- Reusable tableware

- Lids and containers

Polystyrene (PS)

- Melting point: about 90°C

- Applications:

- Styrofoam (EPS)

- Disposable cutlery

- Packaging refills

PS is relatively brittle and heat-sensitive, and thus unsuitable for hot applications.

Polyamide (PA) - Nylon

- Melting point: about 200°C

- Strong, hard-wearing and heat-resistant

- Applications:

- Technical textiles

- Cable ties

- Industrial machine parts

Polyvinyl chloride (PVC)

- Melting point: about 210°C

- Resistant to chemical influences and heat

- Applications:

- Drainage pipes

- Cable insulation

- Flooring

What happens when plastics are mixed?

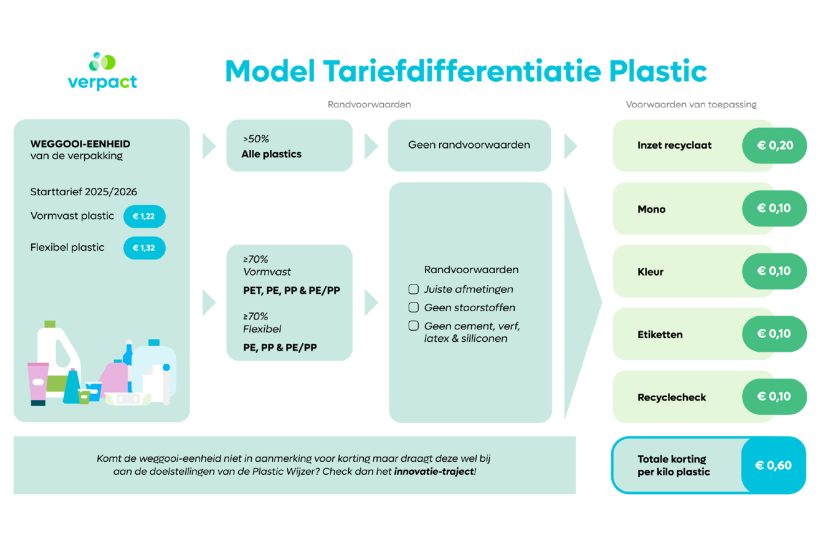

Mixing different plastic types (e.g. at PRC recyclate) directly affects the melting behaviour. Impurities or incompatible plastics can lower the melting point and reduce mechanical strength. This makes these blends less suitable for high-performance applications or products with strict functional requirements.

For example:

- Recyclate originating from mixing streams often has a wider melting range.

- Plastic with admixture of other polymers often loses its original strength, clarity and elasticity.

Note: For direct-food contact, the use of recycled plastic is not allowed, even with a virgin inner layer, in accordance with current legislation and PPWR regulations.

Why is knowledge of the melting point important?

Choosing the right plastic is essential in design and production. Consider:

- Heat-resistant packaging

- Industrial applications with high temperature loads

- Recyclability and compatibility in mixed streams

- Safety standards in food packaging

KIVO responds to this by providing packaging solutions that are technically optimised and PPWR-proof. In doing so, we take into account issues such as:

- Recyclability Grade (A, B or C - with C being the minimum requirement from 2030)

- Use of PIR (post-industrial recyclate) and PCR (post-consumer recyclate), if legally permitted

- Packaging meeting the requirements for design-for-recycling

Conclusion

Plastic melts at different temperatures, depending on the type of plastic. This knowledge is very important in material selection, product safety and sustainability. At KIVO, we help customers select the right plastic for their application, including advice on recycling options and PPWR requirements.

Do you have questions about plastics or sustainable packaging solutions? Get in touch with one of our specialists.

Frequently asked questions (FAQ)

Does plastic melt in the sun?

Some plastics, such as PS or LDPE, can soften with prolonged exposure to sunlight, but will usually not melt completely unless temperatures above 90°C are reached.

What is the highest melting point of a plastic?

Polyimide and polyamide have the highest melting points among standard plastics, often above the 200°C.

Is recycled plastic suitable for all applications?

No. For direct food contact may no PCR (post-consumer recyclate) cannot be used, even if a virgin contact layer is present.